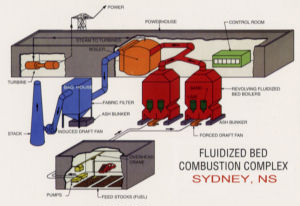

FBC or Fluidized Bed Combustion Click the diagram above to see a larger view

What is it and how does it work?Fluidized beds suspend solid fuels on upward-blowing jets of air during the combustion process. The result is a turbulent mixing of gas and solids. The tumbling action, much like a bubbling fluid, provides more effective chemical reactions and heat transfer. Fluidized-bed combustion evolved from efforts to find a combustion process able to control pollutant emissions without external emission controls (such as scrubbers). The technology burns fuel at temperatures of 1,400 to 1,700 degrees F, well below the threshold where nitrogen oxides form (at approximately 2,500 degrees F, the nitrogen and oxygen atoms in the combustion air combine to form nitrogen oxide pollutants). The mixing action of the fluidized bed results brings the flue gases into contact with a sulfur-absorbing chemical, such as limestone or dolomite. More than 95 percent of the sulfur pollutants in coal can be captured inside the boiler by the sorbent. Pressurized fluidized-bed combustion (PFBC) builds on earlier work in atmospheric fluidized-bed combustion technology. Atmospheric fluidized bed combustion is crossing over the commercial threshold, with most boiler manufacturers currently offering fluidized bed boilers as a standard package. This success is largely due to the Clean Coal Technology Program and the Energy Department's Fossil Energy and industry partnersí R&D. The popularity of fluidized bed combustion is due largely to the technology's fuel flexibility - almost any combustible material, from coal to municipal waste, can be burned - and the capability of meeting sulfur dioxide and nitrogen oxide emission standards without the need for expensive add-on controls. The Clean Coal Technology Program led to the initial market entry of 1st generation pressurized fluidized bed technology, with an estimated 1000 megawatts of capacity installed worldwide. These systems pressurize the fluidized bed to generate sufficient flue gas energy to drive a gas turbine and operate it in a combined-cycle. The 1st generation pressurized fluidized bed combustor uses a "bubbling-bed" technology (The joint Energy Department-American Electric Power Clean Coal Technology project at the Tidd Plant in Ohio used bubbling bed technology). A relatively stationary fluidized bed is established in the boiler using low air velocities to fluidize the material, and a heat exchanger (boiler tube bundle) immersed in the bed to generate steam. Cyclone separators are used to remove particulate matter from the flue gas prior to entering a gas turbine, which is designed to accept a moderate amount of particulate matter (i.e., "ruggedized"). A 2nd generation pressurized fluidized bed combustor uses "circulating fluidized-bed" technology and a number of efficiency enhancement measures. Circulating fluidized-bed technology has the potential to improve operational characteristics by using higher air flows to entrain and move the bed material, and recirculating nearly all the bed material with adjacent high-volume, hot cyclone separators. The relatively clean flue gas goes on to the heat exchanger. This approach theoretically simplifies feed design, extends the contact between sorbent and flue gas, reduces likelihood of heat exchanger tube erosion, and improves SO2 capture and combustion efficiency. A major efficiency enhancing measure for 2nd generation pressurized fluidized bed combustor is the integration of a coal gasifier (carbonizer) to produce a fuel gas. This fuel gas is combusted in a topping combustor and adds to the combustor's flue gas energy entering the gas turbine, which is the more efficient portion of the combined cycle. The topping combustor must exhibit flame stability in combusting low-Btu gas and low-NOx emission characteristics. To take maximum advantage of the increasingly efficient commercial gas turbines, the high-energy gas leaving the topping combustor must be nearly free of particulate matter and alkali/sulfur content. Also, releases to the environment from the pressurized fluid bed combustion system must be essentially free of mercury, a soon-to-be regulated hazardous air pollutant. To reduce cost and carbon dioxide emissions, new sorbents are being evaluated. Sorbent utilization has a major influence on operating costs, and carbon dioxide emissions streams can result in the production and use of alkali-based sorbents. Efforts are ongoing at the Power Systems Development Facility (PSDF) in Wilsonville, Alabama to ensure critical components and subsystems are ready for demonstration of 2nd generation pressurized fluidized bed combustion. The PSDF is operated by Southern Company Services under DOE contract to conduct cooperative R&D with industry. Tests conducted at the PSDF in 1998 verified that a newly developed multi-annular swirl burner (MASB) provided the needed flame stability and low-NOx performance characteristics. Tests of promising new hot gas filter components and systems are continuing at the PSDF. Advances made to date in this critical technology area include the development of clay-bonded silicon carbide candle filters and the associated filter vessel. Efforts are currently focused on improved candle filter materials for enhanced durability under extreme temperatures and corrosive environment. New ceramics and ceramic-metallic composites are showing promise. Those passing laboratory screening tests will undergo testing at the PSDF. Our thanks for the above explanation to Faith Cline at the U.S. DOE Sydney's tar Ponds FBC technology explained (SERL) CANMET Energy Technology Center FBC Program |